Large Format Slab System

LARGE FORMAT SLAB SOLUTIONS

Large format slabs are expensive, and their large size increases the difficulty of handling them, as well as the risk of damage. To address these issues, TILER has developed and designed a complete range of products specifically tailored for large format slabs. The TILER Large Format Slab System is designed to ensure the safe and efficient handling of slabs throughout the installation process. This includes workbenches that can accommodate large format slabs, as well as manual and electric cutting machines specifically designed for cutting large format slabs, catering to the cutting needs of installers working with various thicknesses of tiles.In addition, there are equipment available for efficient and effortless transportation of large format slab tiles.

LEARN MORE: What is large format tile ?

https://www.tilertool.com/n1894171/What-is-Large-Format-Tile.htm

https://www.tilertool.com/n1894171/What-is-Large-Format-Tile.htm

APPLICATION

Large format slab universal size

24 x 48 inch (60 x 120 cm)

30 x 60 inch (75 x 150 cm)

48 x 48 inch (120 x 120 cm)

60 x 60 inch (150 x 150 cm)

60 x 120 inch (150 x 300 cm)

63 x 126 inch (160 x 320 cm)

71 x 118 inch (180 x 300 cm)

71 x 138 inch (180 x 350 cm)

79 x 158 inch (200 x 400 cm)

Flooring

Wall cladding

Counter-tops

Outdoor spaces

SLAB SYSTEM

Slab Cutter

Working Bench

Carrying System

19 results

ViewShowcase

TILER Large Format Slab Manual Cutter DB-2 is specially designed for cutting porcelain stoneware slabs up to 336cm.

TILER Slab Manual Cutter DB-3 is designed specifically for cutting large stone slabs, suitable for various dimensions.

TILER Large Format Slab Working Bench DB-TB-3 180cm is specially designed for working with large-format porcelain tiles.

Large Format Slab Workbench TYF-DB-TB-3 360cm | Spacious and Durable|Perfect for Large Slab Handling

TILER Large Format Slab Workbench DB-TB-3 360cm is specially designed for working with large-format porcelain tiles.

We offer robust slab working benches for efficient handling. We are a trusted manufacturer of quality tiling tools.

TILER Large Format Slab Carrying System DB-CY-2 is specially designed for handling large format slabs up to 360 cm in length.

TYF-DB-CY-04 Large Format Slab Handling System with Electric Vacuum Suction Cups | Perfect for OEM/ODM and Wholesale Partnerships.

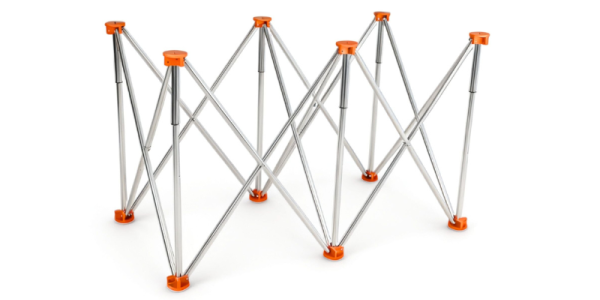

DB-TB-6 Large Format Slab Centipede Workbench (6 Legs) - Perfect for tiling and cutting. OEM & ODM options available for bulk buyers.

Discover the DB-TB-5 Large Format Slab Centipede Workbench (15 Legs) - Factory Direct OEM/ODM for efficient wholesale tile cutting solutions.

DB-TB-6 Large Format Slab Centipede Workbench (6 Legs) - Perfect for tiling and cutting. OEM & ODM options available for bulk buyers.

TILER Large Format Slab Cutter 2 in 1 Kit DE-125X suitable for cutting large format slab with a thickness of 4 to 25mm.

TILER The Large Format Slab Trolley is a versatile and efficient tool designed for transporting large format slabs with ease.

TILER Large Format Slab Carrying System DB-CY-3 is tool for lifting, handling and laying of large format and heavy duty tiles.

TILER A24302 is an accessories for DB-2 the large format tile cutter ,provides precise straight cutting with high efficiency .

TILER DE-125M is a powerful tool designed for cutting and shaping marble and other types of stone with precision and ease.

The TILER A24305 Tile Cutting Plier is a precision tool designed for use with the DB-2 tile cutter, used for clean cut of tile.

TILER A24301 Guide Rail is an aluminum accessory that is used to guide large format tile cutters for accurate and straight cuts

TILER A24304 ensures that the slab cutting work is gradually separated, minimizing the risk of improper breakage.

TILER A24303 is a rubber accessory used to securely fix rock slabs on the DB-2 cutting machine for precision cutting.

large format slab system Information

TILER offers a complete range of tools specifically designed for cutting, handling, and installing large-format porcelain slabs. With the increasing popularity of these materials, TILER offers a selection of tools that provide solutions for the transportation and installation of these special materials.

TILER's line of products includes a range of cutting solutions, such as the manual cutter and the electric cutter. The best solution for cutting porcelain slabs on the market, TILER's cutting system is complemented by a range of transport and handling elements, which make it easy to transport and install these materials.

Large Format Slab Cutter DB-2: Large format slab cutters are ideal for use in the installation of large format tiles where precision cuts are required. This is a tool designed for cutting large format porcelain sheets of up to 4-12 mm thickness. It features a cutting wheel and a guide rail that allows for straight and precise cuts. This model also comes with a separator that helps prevent breakages during cutting.

Large Format Slab Working Bench DB-TB-3: This is a specialized workbench designed for handling and cutting large format porcelain slabs. It typically features a large, flat surface that provides a stable cutting surface for the slab cutter.

Large Format Slab Carrying System DB-CY-3:This system is designed to facilitate the transportation of large format porcelain slabs. It includes products such as transport carts, suction cups, and carrying straps. These products help to make the ride of large-format porcelain slabs safer, easier, and more efficient.

Large Format Slab System Accessories: This is a range of accessories that are designed to complement the large format slab cutter, working bench, and carrying system. Some of the accessories available include separators, crossbars, and leveling systems. These accessories enhance the performance of the large format slab system and help to ensure that the installation of large format porcelain sheets is carried out with precision and accuracy.

TILER's commitment to providing high-quality tools and excellent customer service makes it the go-to choice for professionals who demand the very best.

Another advantage of using a manual tile cutter is that it doesn't require electricity, meaning that you can work anywhere on the job site without needing a power source nearby. Unlike power tools, manual tile cutters don't require water cooling, providing a great level of autonomy while working in any location, without the need for a water supply or creating a wet or dirty surrounding area. Therefore, manual tile cutters are reliable tools, providing the ability to make accurate and clean cuts on any kind of ceramics, including porcelain, which is a common material used in tiling projects.

One interesting point about manual tile cutters is the low cost of consumables. Scoring wheels are long-lasting and low-cost tools that can be used to make many cuts in a cheap and easy way. In addition, they are very easy to replace on TILER manual tile cutters, allowing you to change the scoring wheel whenever you need a different type or when it wears out.

video display

Subscribe to Get Latest Updates

Contact us

- Name:

- Hangzhou John Hardware Tools Co.,Ltd

- Tel:

+86-571-88637866

- Email:

- info@tilertool.com

- Address:

- Building 1, No.283 Renkang Road, Renhe Street, Yuhang District, Hangzhou, Zhejiang, China 311107

Get a special discount for your first order !

GET A SPECIAL DISCOUNT FOR YOUR FIRST ORDER!

- Name

- Mobile Phone

- *Title

- *Content